SRI value:

Amount of dirt on surface after cleaning.

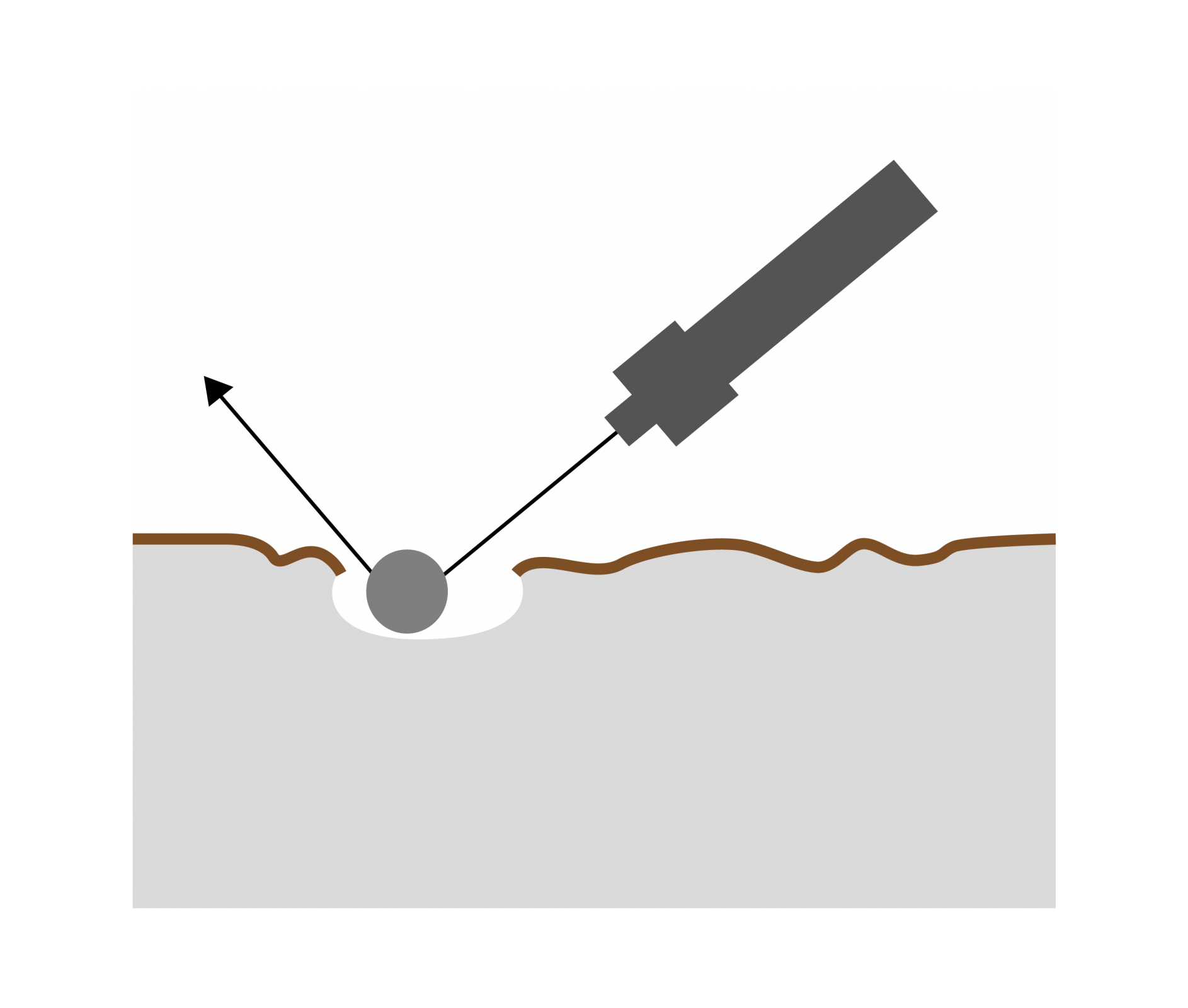

H2Ofinish

SRI < 0,010

More information

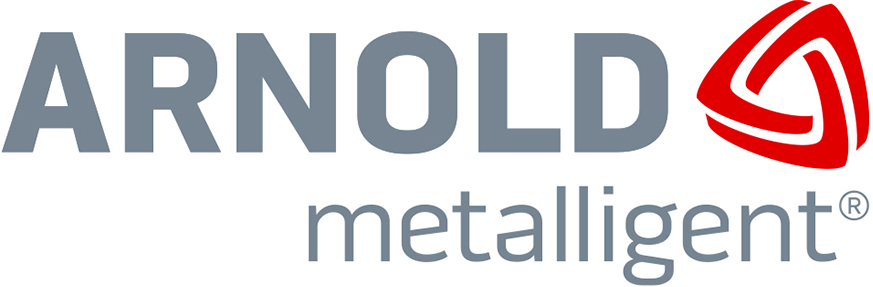

Dry blasting

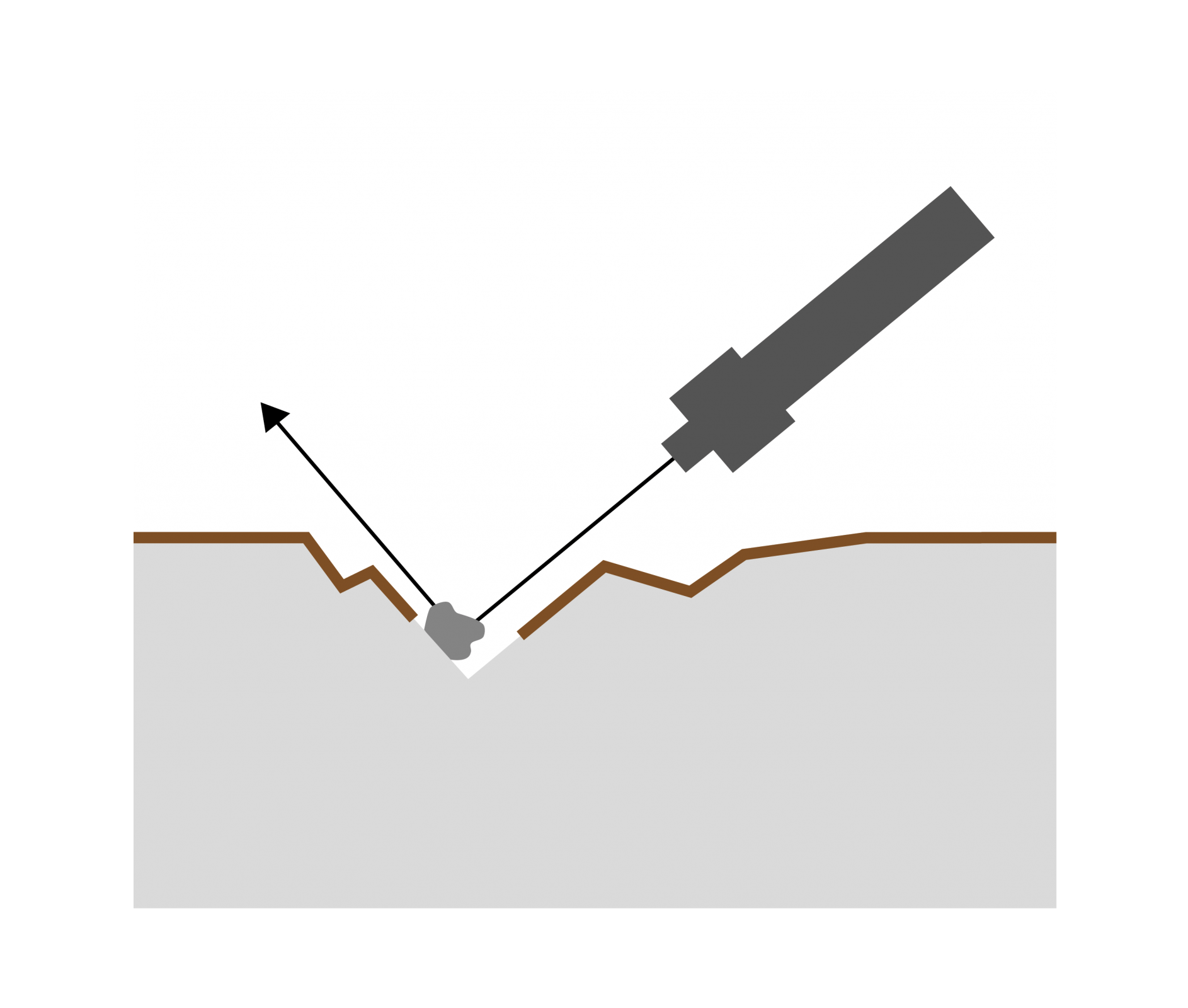

Glass bead blasting

Wetblasting